Jig grinding is a process utilized when a high degree of machining accuracy is required. Although it’s not the exact same thing as jig boring, the two processes are similar. Let’s take a look at jigs, machining and why they make the process more accurate and precise.

What is a Jig?

A jig can be referred to as a “template” for a work piece. For example, if you would like to have a spare house key made, the locksmith (or store employee) places your key into a special key machine. The key becomes the jig for the duplication process. Jigs are a very important part of production because they help to create exact duplicates of many intricate and close tolerance parts.

Uses for Jig Machines

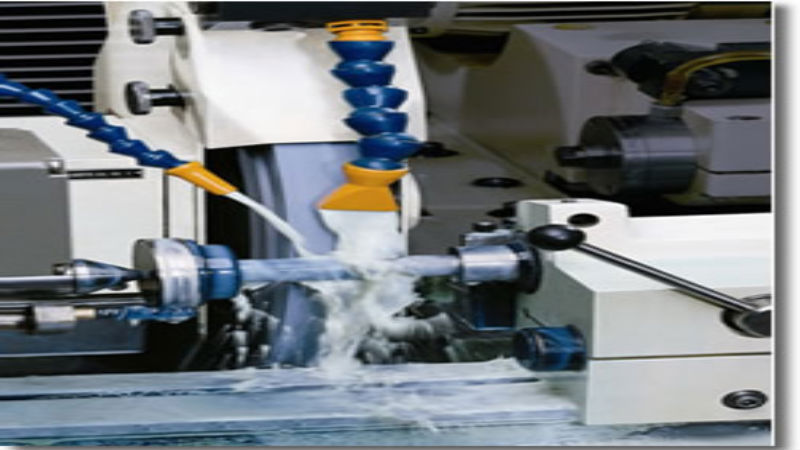

Jig borers are often used when you need several holes of varying sized drilled in a specific pattern. This is the best way to prepare specific parts for assembly and it eliminates a great deal of the hard work and time associated with creating the original part (jig). Jig grinding achieves the same basic purpose.

Jig grinders are used in a number of applications today. For example, in the injection mold industry, detail and accuracy are essential and jig grinders can deliver exactly what is needed. Tool and die makers rely on the machines for a great deal of work. They can create a wide range of complex and detailed shapes besides making high tolerance holes.

Is Jig Grinding the Best Option?

In some cases, there is an alternative to using a jig machine. For example, some people prefer a method known as EDM, especially for working with prototypes and injection molds. Here is more about the process.

Electrical Discharge Machine

The EDM process works on electricity. In the 18th Century, a man named Priestley discovered electrical discharge could remove material from objects. Today’s EDM methods are sophisticated and many use a wire cutting method in which a wire with electric current passes through the material. This is usually done in a dielectric environment. The process works well because of the intense heat it develops and is sometimes called “spark erosion”.

Problems with EDM

Although EDM can be effective, it is not without a downside. For example, the method is relatively slow because it takes a while for spark erosion to occur. In addition, there is a risk involved with fire hazards associated with using some dielectric materials. Plus, this process can use a great deal of electricity and may not be the most efficient operation. For many businesses today, jig grinding is the preferred choice.