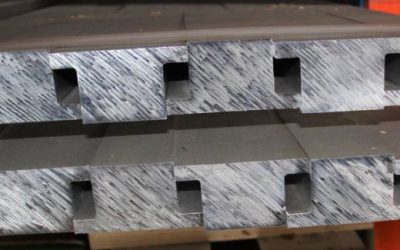

Using a cast aluminum tooling plate can significantly enhance precision and efficiency in various machining and manufacturing applications. Cast aluminum tooling plates, known for their flatness, durability, and stability, have gained popularity in industries such as aerospace, automotive, and precision engineering. Here is why using cast aluminum tooling plates is a valuable choice.

Exceptional Flatness

Cast aluminum tooling plates are manufactured with a high level of flatness. This flatness tolerance ensures that when machining or assembling components on the plate’s surface, the result is accurate and consistent. It is a crucial factor in applications where tight tolerances are a requirement. When you need the results to be extremely precise, it is a wise choice to go with a cast aluminum tooling plate.

Stability and Rigidity

Cast aluminum tooling plates are inherently stable and rigid, thanks to their dense, uniform structure. This stability ensures that the plate remains flat and does not warp or deform under heavy loads or temperature variations. In precision machining and manufacturing, this stability is essential for consistent and reliable results. You can get these results when you use a cast aluminum tool and jig plate.

Cast aluminum tooling plates offer a reliable and precise surface for a wide array of machining and manufacturing processes. Their exceptional flatness, stability, corrosion resistance, versatility, and ease of machining make them a valuable investment for industries where precision and consistency are paramount. Whether in aerospace, automotive, or other precision engineering applications, the use of cast aluminum tooling plates can greatly enhance equipment.