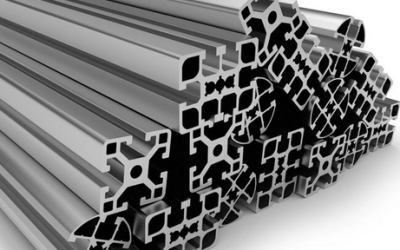

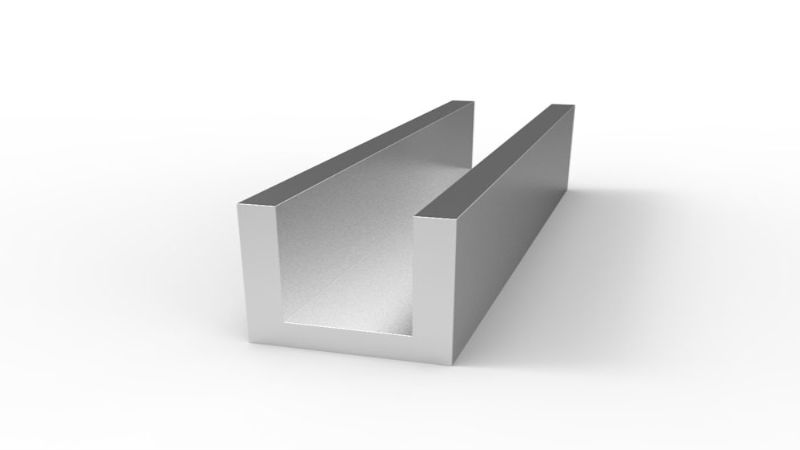

T track is used in many different types of applications. Since it is designed to allow easy movement along the “track” by anything with the correct T-shaped head, it can be used in jigs, fixtures, with woodworking equipment and in a wide variety of industrial applications.

The T track aluminum is solid and durable and easily allows for complete control of tools or material along specific pathways. It can also be used for fabrication of components that need to be taken down and reassembled frequently or those that need adjustment easily.

Cutting T-Track

It is important to cut T track aluminum correctly to ensure a straight and even cut without any crimping down on the ends of the track that would inhibit movement of inserts along the track.

This an aluminum product, so it doesn’t need a lot of pressure to cut through the metal. It can be cut with a steel blade with a hacksaw or it can be cut using carbide tipped blades on a table or circular saw or a miter saw. Choosing a blade with multiple fine teeth also creates a nicer edge. Be very careful not to press down with force on the saw, particularly when using a handheld circular saw or band saw.

Finishing Cut Edges

It is very common after cutting T track aluminum using any method to have some burrs and sharp edges. Use a fine metal file to brush off the burrs and remove any shards of metal that can end up in the tracks.

You may also want to use some sandpaper to make a mirror finished shine on the edge. However, if the T-track is going to be inset into wood for a jig there may be no need for this additional finishing step.

Depending on the company you order from, you may be able to order in lengths that are pre-cut and will not require any additional work. Just ask when you are making the purchase of T track aluminum to see if this service is available.