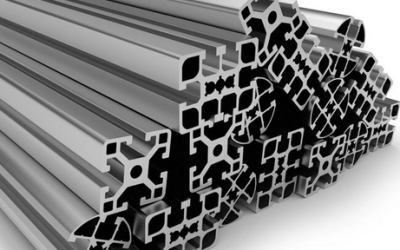

For many applications, aluminum that is shaped to a specific form is a central component in the design and manufacturing. Simple shapes such as channels, angles, tubes, pipes and the Z shapes used in various types of construction and fabrication are all components that are used on a daily basis.

Each of these shapes has to be formed through the extrusion process. This includes heating large ingots or billets of aluminum weighing thousands of pounds into a semi-liquid state, then forcing that, under pressure, through the specially designed die.

Additionally, the chamber where this occurs is carefully controlled for temperature and atmosphere. This allows for the aluminum extrusion shapes to be free from any surface defects or issues that could limit their use.

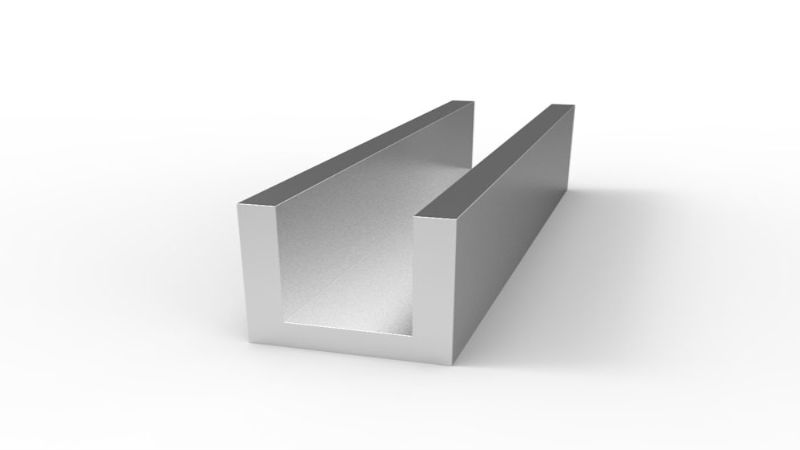

Channels

Any type of channel is designed to include a solid outer component and a hollow interior component that is open to one side. A common option would be a T channel, where the channel itself looks like the top of the capital T.

This type of extrusion is used for jigs, tables, shelving components and for racks. It is extremely versatile and can be found in a large number of manufacturing and fabricating uses.

Angles

Angles tend to include aluminum extrusion shapes that are two sided. They can include both American Standard equal angles or unequal angles, and they are often used in the manufacturing of trailers, boats, and other types of equipment.

These types of standard shapes, as with all standard shapes, are available in a variety of different finishes. These include mill finish, which has slightly circular patterns in the finish, polished, which is smooth and even, or brushed, which has a slightly matte appearance.

Angles can be designed to have longer or shorter measurements on the upper or lower leg of the angle, but they offer a right angle regardless of the measurement.

Tubes and Pipes

Tubes and pipes may look the same, but they are different in their measurement. Tubing is measured by the exact outside diameter, and the wall thickness is also specified. Pipe, which is commonly used for gasses and liquids, and are measured by a nominal outside diameter and corresponding wall thickness.

Typically pipe is going to be round in shape while tubes can be round, square, split or rectangular.

Rod and Bars

Rod and bars are aluminum extrusion shapes that are similar to tubing, but they are solid and not hollow. Rod is always round, while the shapes of bars can be rectangular or square.

To make things even more specific, it is possible to have a rectangular bar with round ends. This creates a flattened elliptical shape that is used for many types of finishing components.