When designing a system that handles the flow of a liquid, choosing the right solution for the specific needs of the system will be a very important choice. Designers and engineers carefully assess each component to ensure it is capable of standing up to the temperature, pressure and the demands of a specific system.

Systems in any type of chemical, food or beverage production, water supply or processing facility are always designed to run in one direction. To prevent the materials in the pipes from reversing direction due to a pressure drop from a break in a line or a failure of motor, ball check valves can be put in place.

Automatic Regulation

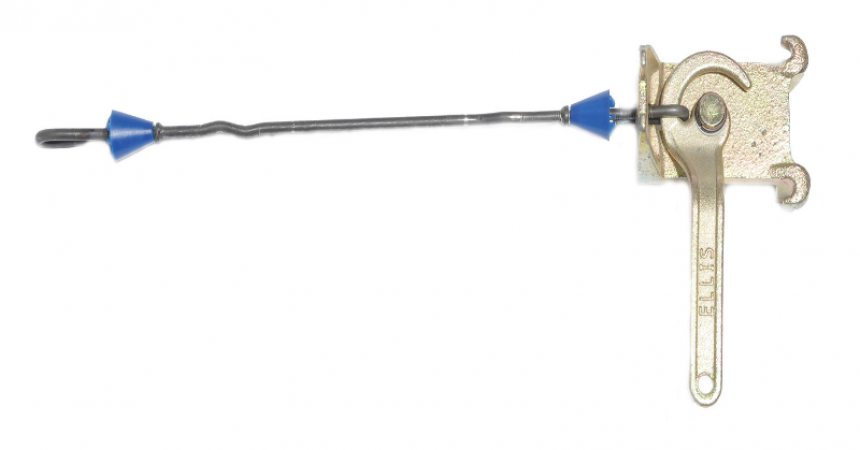

Unlike other types of valves, including standard ball valves, the function of ball check valves is not to control volume or speed of a liquid through the system. This means that these valves typically do not have any external handles or controls.

Instead, within the valve, there is a full or a half ball. With the half ball design, the rounded or convex side sits against the inlet port to the valve. As the water or liquid moves through the system, it pushes against the rounded side of the half ball or full ball and around the edges to the outlet port.

Should the pressure drop on the inlet side, it is possible the liquid could reverse on the outlet port and flow back if the full or half ball wasn’t there. With the design of the ball check valves if this happens the reversing liquid simply pushes the ball into the seal, effectively sealing the valve and preventing any backflow through the system.

Choosing the correct ball check valve will require an understanding of the temperature, pressure, and fluid through the system. The design options of the full or half ball will also need to be considered without the parameters of the system.