Do you have a system or an application that is not working properly because of the couplers or connectors? It is not uncommon for these types of components to fail. Over time, the normal wear and tear and use of them can cause just the smallest amount of dysfunction. In a matter of months, they can pose a higher risk, though. If you have quick disconnect hydraulic couplers that are not working the right way, be sure to change them out immediately. This helps ensure that the safety and integrity of your system remain in place.

Choosing the Right Product Matters

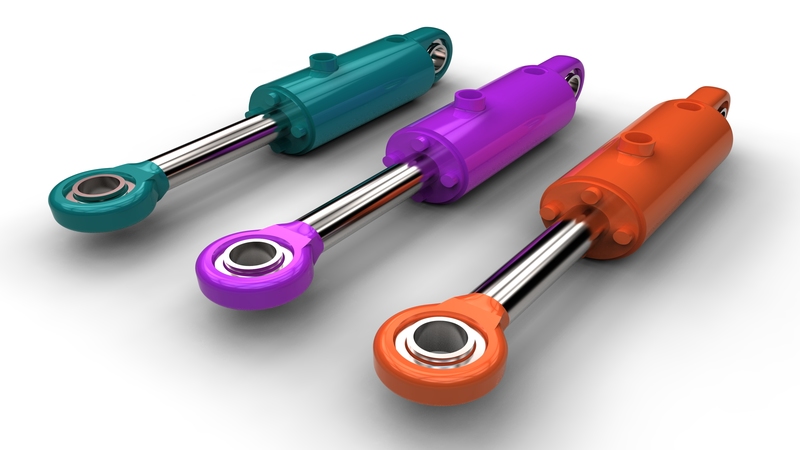

If you do need to change the quick disconnect hydraulic couplers, there are a few key things to keep in mind. Most importantly, you need to know the size, style, and function of your system. You also need to know the type of material they are made out of and any specific features or design components to them. It is critical to replace these with exact duplicates. Anything else creates a higher risk of failure for your system, putting the system and your employees at a safety risk.

To avoid this, work with a manufacturer and distributor to find the couplers you need. The good news is that these systems can be highly effective and easy to find in most cases. If your system is older or is no longer being manufactured, you may need to work with the company to design a specific component for your system. It may be easier to do this than you realize.

With quick disconnect hydraulic couplers, it is important to keep them in good condition long term. As soon as you notice any changes in them or the way they operate, replace them to avoid any type of risk or system failure occurring.