In today’s increasingly competitive economy, having access to dependable and high-quality resources is vital to the success of any company. Because of its versatility, strength, and lightweight qualities, aluminum is used extensively in industries such as buildings, automobiles, and manufacturing. Forming a connection with the proper supplier can significantly improve a company’s ability to accomplish project objectives, uphold quality standards, and maintain a competitive advantage. Choosing a supplier is more than just purchasing goods; it entails developing a solid connection with a dependable partner who appreciates product integrity, on-time delivery, and customer happiness.

Assessing Product Quality and Range

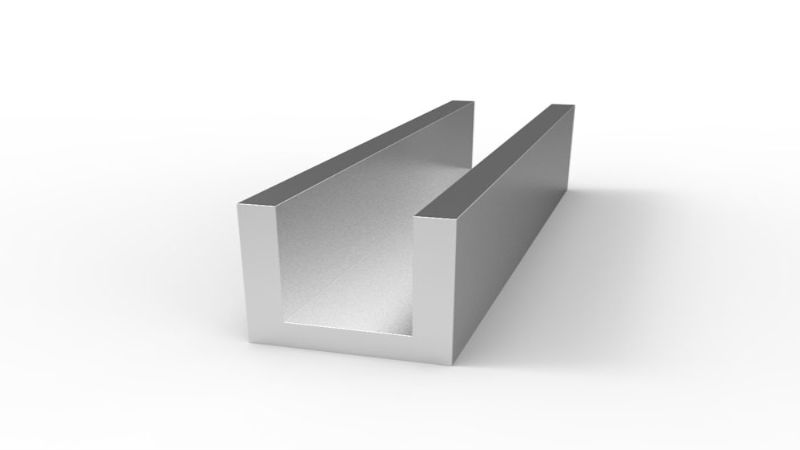

When choosing aluminum suppliers, one of the first things to examine is the quality and variety of products they provide. The quality of aluminum, whether used in construction, transportation, or manufacture, has a direct impact on the end product’s longevity and performance. Reliable suppliers often provide a wide range of aluminum goods, such as sheets, plates, bars, and bespoke extrusions, to ensure that different project requirements are met. In addition to having a large inventory, a top-tier supplier will follow industry certifications and quality control procedures. This ensures that the materials supplied meet international requirements for strength, corrosion resistance, and other key characteristics. Inquire with potential suppliers about their certifications and the quality assurance systems they use to provide consistent, high-grade aluminum. A good supplier not only fulfils your company’s current needs but also can scale as it grows.

Importance of Efficient Logistics and Reliable Service

Another valuable issue to consider is the supplier’s ability to provide materials quickly and effectively. Lead times might vary substantially based on production capacity, order size, and the distance between the supplier’s location and your company. Finding aluminum suppliers with an effective logistics network promotes timely delivery, reduces downtime, and helps keep projects on track. Consider providers with a proven track record of dependability, as any disruption in the supply chain can have a domino impact on production schedules. These value-added services help ensure that you have the materials you need at the right time without the hassle of managing extra inventory. Customer service is another crucial aspect of a successful supplier partnership. The finest suppliers will provide personalized account management and technical support to aid with product selection, problem-solving, and project planning. A responsive and skilled team can provide insights into material performance, troubleshoot issues, and advise on the most cost-effective solutions for your company.

Cost Efficiency Without Compromising Quality

While cost is always a consideration when selecting a supplier, it’s critical not to prioritize price over quality. Although lower-cost suppliers may appear appealing at first, inferior materials can result in higher long-term expenses owing to rework, product failures, or decreased durability. Balancing affordability and quality should be the goal, ensuring that you acquire products that meet the appropriate criteria while remaining within your budget. A reputable provider can assist you in managing the complexity of pricing by providing competitive rates without sacrificing quality. They can also supply information about market trends, allowing you to make strategic purchasing selections. Bulk purchases, long-term contracts, and volume discounts can all help to reduce costs while maintaining material requirements.