Over time, manufacturing processes have improved and time-saving equipment has been invented. Electrical discharge machining (EDM) is indispensable to today’s best machine companies.

What Precision Wire EDM Service is

EDM removes metal in a controlled manner by melting it instead of cutting it. More specifically, electric spark erosion vaporizes materials. Precision wire EDM service is highly accurate and leaves behind little wasted material.

What Materials Can be Used for Wire EDM Processing

Ferrous materials consist of at least 50% iron. Conductive materials used in wire EDM service include both ferrous and non-ferrous materials.

Ferrous Materials Used:

- Stainless steel

- Invar

- Carbide

- Bronze

- Iron

- Carbon and alloy

- Tool

Non-Ferrous Materials Used:

- Platinum

- Gold

- Silver

- Brass

- Copper

- Aluminum

- Titanium

- Tantalum

- Tungsten

- Cobalt

- Tin

- Hastelloy

- Inconel

- Monel

Applications for Premier Wire EDM Service

There is a wide range of applications for premier wire EDM service. Most notably, wire EDM service is great for gear, spline and die and mold fabrication, as well as for prototyping and making medical devices.

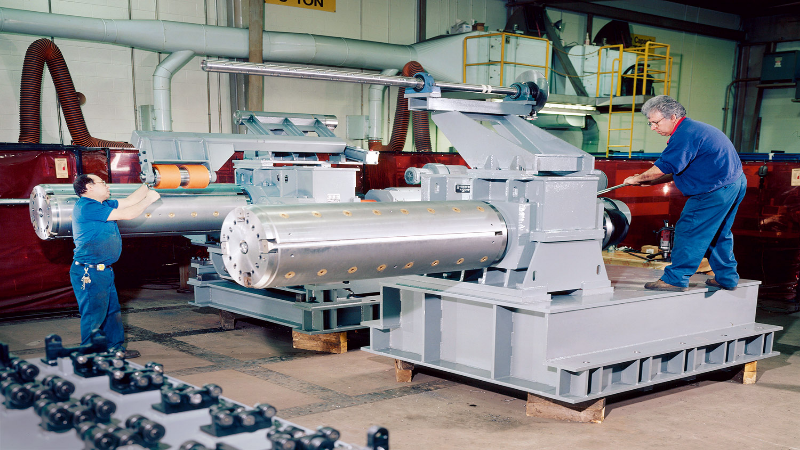

What Makes an Exceptional Wire EDM Shop

An exceptional wire EDM shop would have ITAR registration and would be ISO and NIST-compliant. Decades of experience and a well-deserved great reputation would add even more credibility. The wire EDM process is fast and autonomous, accomplishing more with fewer people. The best wire EDM equipment easily handles both hard and brittle materials, as well as large or complex parts. They’re also highly accurate (0.0001 tolerance).