For completing or finishing a specific project, manufacturing industries can select one of several options. Machining is a popular means of finishing off a workpiece, so it best suits its function. Selecting the right tool to perform the task can be complicated. However, many look to grinding machinery to provide them with the results they need. They talk to machine shops about whether the answer lies in surface or cylindrical grinding machinery.

The Cylindrical Grinder

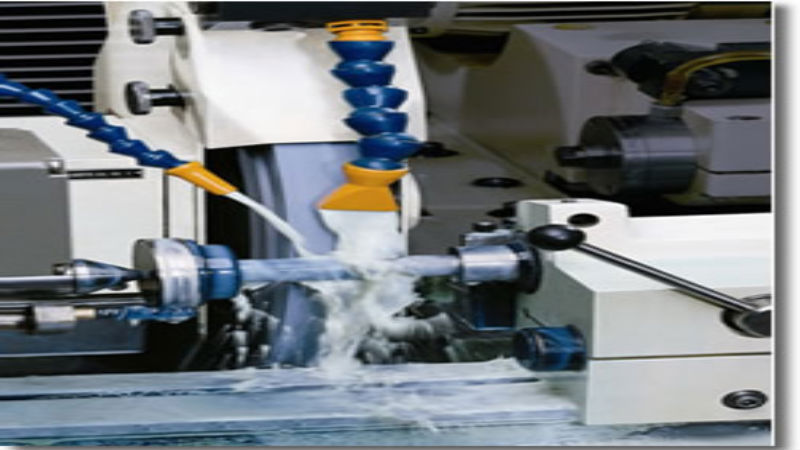

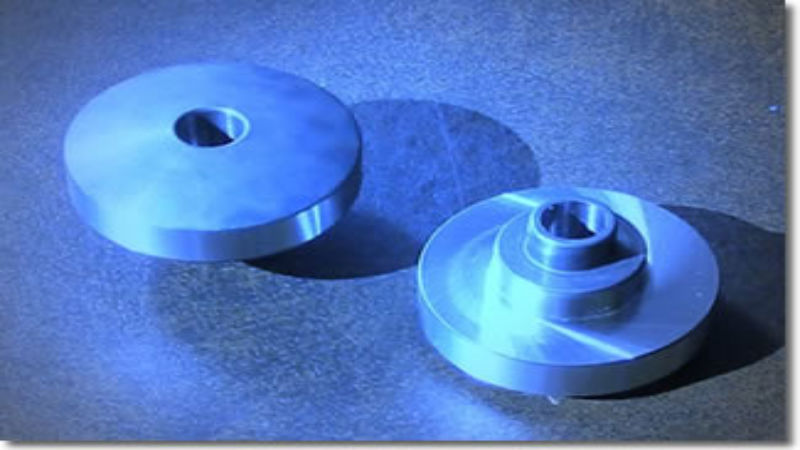

Among the grinders capable of producing high-quality results, cylindrical grinders stand out for certain projects. The machine applies an abrasive tool for cutting away minute particles slowly and precisely. It also provides the material of a workpiece with the high-quality finish characteristic of this type of grinding. The surface of a workpiece finished by a cylindrical grinding machine is smooth – lacking the customary roughness commonly resulted from other machine or fabrication techniques.

When purchasing a cylindrical grinder, companies have their choice of outside diameter (OD) grinders, inside diameter (ID) grinders, and centerless grinders. Each kind of cylindrical grinder best serves a specific type of industrial usage. It is important to consider the merits of each type in relation to the intended function.

Industrial Applications

Cylindrical grinders are most commonly employed to produce precise shapes and superior surfaced products. These components are in high demand in many different industries. A small sample includes parts made for the following manufacturing concerns:

- Automotive e.g., bearings, rods

- Electrical e.g., rods, bearings

- Military e.g., rods, bearings, bushing

- Plumbing e.g., bearings, bushings, tubes

Cylindrical Grinding

As a finishing process, grinding offers so much. Whether the need is for the production of precise metalwork for a military project or to satisfy the demands of the automotive industry, machine shops offer their customers a variety of grinding processes to finish their components. When looking for high-quality results and very precise results for shapes uniquely designed shapes, a grinding shop often recommends cylindrical grinding.