The importance of finding the right company to handle specialized aspects of production and fabrication cannot be underestimated. When you are working with a company that is professional, understands your expectations and can complete the work to the tolerances and specifications you need, you have found an ideal partner.

CNC Options for Precise Grinding

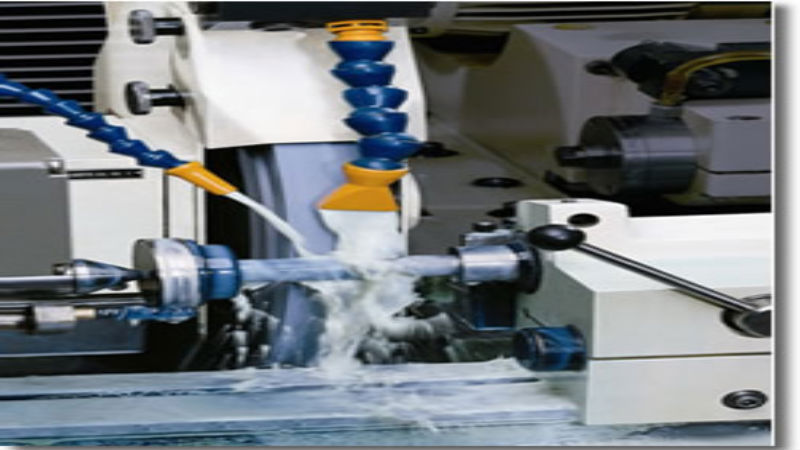

One of the most common manufacturing and fabrication tasks required is CNC grinding. This is common for both internal and outside diameter grinding needs with this type of CNC cylindrical grinding requiring both specialized equipment as well as expertise in setting the program to achieve the required tolerances.

In addition to the CNC cylindrical grinding, there is also the option to use computer numerical control (CNC) for thread grinding. The advanced technology allows for a range of different thread types including variable pitch threads, metric, taper and up to 32-degree helix angles for any threading requirements.

What to Consider

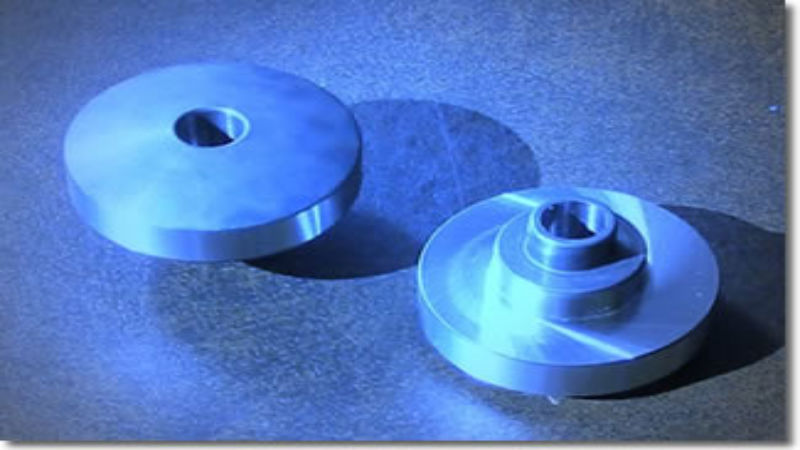

When considering a company to provide CNC grinding, stop and look at the other services they offer in addition to the grinding services. Many of the top companies are able to provide honing, jig grinding, flat and bar grinding as well as centerless grinding and lapping.

By choosing a company to complete your CNC grinding that also offers other metal grinding and finishing options, it is easy to simply the logistics of the shipment and also to take advantage of the benefits of working with just one outside service.

Not all companies offering CNC services for various types of grinding will take on all types of jobs. Some only work with large volume orders while others may specifically provide services as prototype developers. There are also companies that are able to do it all, with these companies typically providing the best options in service with the expertise and experience to handle any job.