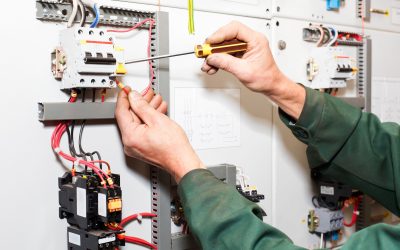

Electrical equipment forms the backbone of modern infrastructure, powering industries, homes, and essential services. However, neglecting repairs and maintenance of such critical assets can lead to significant risks. From safety hazards to operational disruptions, postponing electrical equipment repairs and maintenance in New Jersey poses dangers that shouldn’t be underestimated.

Safety Compromises

Postponing repairs on electrical equipment increases the risk of safety hazards. Malfunctioning machinery can lead to electrical fires, electrocution, or equipment failures, endangering workers and property. Without regular maintenance checks, faults can escalate, resulting in catastrophic accidents.

Decreased Efficiency

Delayed repairs often result in reduced equipment efficiency. Over time, minor issues can escalate into major faults, impacting productivity and increasing downtime. Machinery operating below optimal levels consumes more energy, leading to higher operational costs and decreased profitability.

Compliance Violation

Neglecting electrical equipment repairs and maintenance in New Jersey can lead to non-compliance with industry regulations and safety standards. Many jurisdictions mandate regular inspections and upkeep of electrical equipment to ensure safe working environments. Failure to adhere to these standards can result in fines, legal liabilities, and reputational damage.

Cost Escalation

Postponing repairs might seem like a cost-saving measure, but it can lead to equipment failure in the long run. Small issues left unattended can escalate into major breakdowns, necessitating expensive equipment failure repair in New Jersey. Additionally, operational disruptions caused by equipment failures can result in lost revenue and damage to customer relationships.

Contact JET Electrical Testing, LLC for quality electrical equipment repairs and maintenance in New Jersey.